ROPE MANIPULATOR

Ideal for any sector and application field including:

Automotive

Food Industry

Chemical

Construction

Electromechanical

Pharmaceutical

Foundries

Packaging

Woodworking

Textile

Mechanical

Ceramic

Home appliances

Tobacco

Tire production

Rubber and plastic

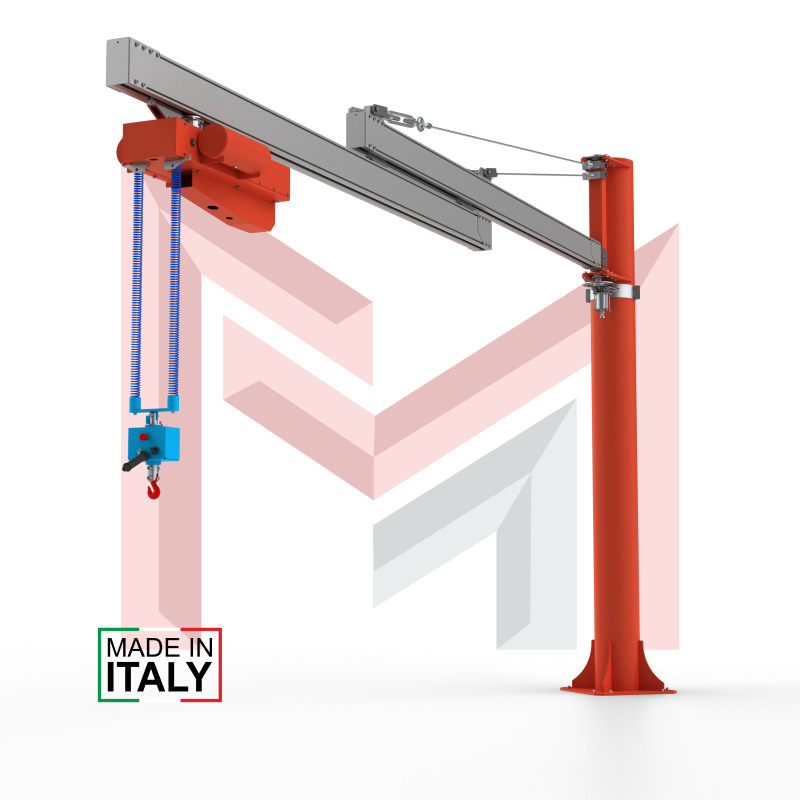

TEIA

Pneumatic cable manipulator

TEIA pneumatic cable manipulator is a double rope balancer installed on a rail with a capacity of up to 180 kg, allows an extremely versatile configuration of the work area, offering the possibility of covering areas that cannot be reached with conventional manipulators

Solutions to increase work efficiency and move heavy loads with precision

TEIA pneumatic cable manipulator is an industrial pneumatic lifting solution designed to ensure exceptional versatility and precision in the handling of heavy and bulky loads. Thanks to their ability to adapt to various configurations and work environments, these zero-weight devices allow operators to perform lifting and moving operations with ease and precision. Each Maniflex balancer is designed to handle heavy loads, avoiding physical effort for the operator and ensuring maximum safety.

How do pneumatic industrial cable manipulators work?

The balancing system is simple and efficient: two steel cables connected to the pneumatic cylinder distribute the weight of the load evenly. The weight is supported by the manipulator while the operator manages the movements without any effort.

Installation flexibility

The TEIA series pneumatic industrial manipulators can be installed in multiple configurations to meet your space and layout needs. They are available for mounting on a fixed column on the floor or on a self-stable base, fork-liftable for transport with a forklift or pallet truck. Furthermore, they can be fixed to the wall, or on floor or ceiling rails. Upon request, it is possible to obtain additional special supports, customizable according to the specific needs of the customer.

Smooth and precise movements on rails

Another peculiarity of TEIA manipulators is their mounting concept. The load moves on an aluminum rail that makes it easy to handle and guarantees precision throughout the working area.

Safety and reliability

To ensure maximum safety, the manipulators are equipped with two brakes on the rotation axis of the arms. They operate with filtered (40 μm) and lubrication-free compressed air, with a minimum pressure of 0.7/0.8 MPa, thus ensuring stable and long-lasting operation over time.

Advantages:

- Articulated movement for precise positioning of loads.

- Operating speed of grip and release

- Uninterrupted Operation

- Simple design makes it easy to use

- Improving safety for operators

- Cost containment through error reduction

- Flexibility in configurations and operations

- High precision and consistent quality of finished products

Technical features of TEIA pneumatic cable manipulator

- Maximum capacity: 180 kg

- Maximum radius: 6,000 mm

- Vertical lift: 1,600 mm

- Maximum air consumption: 68 nl/min

TEIA pneumatic cable manipulator - available mounting options

Some examples of TEIA series mounting options

Floor mounted column fixed on the ground with chemical anchors

Baseplate mounted free standing

Column mounted with baseplate on floor rails

Overhead or wall mounting bracket

Rail mounted overhead trolley system

Ceiling mounted bridge system combined with floor rails