Rigid arm manipulator

Ideal for any sector and application field including:

Automotive

Food Industry

Chemical

Construction

Electromechanical

Pharmaceutical

Foundries

Packaging

Woodworking

Textile

Mechanical

Ceramic

Home appliances

Tobacco

Tire production

Rubber and plastic

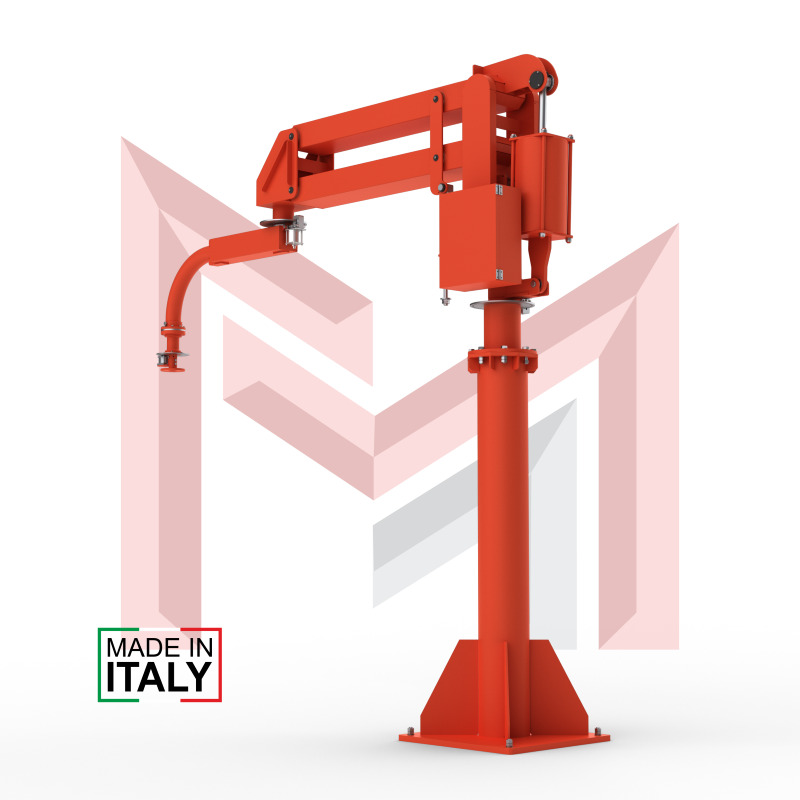

CRIUS

Rigid arm industrial manipulator

Rigid arm industrial manipulator with articulated rigid arm with a maximum capacity of 750 kg, suitable for the controlled or zero gravity handling of large and heavy loads with maximum ease and precision, capable of positioning the load with maximum precision thanks to the customized tools.

Solutions to improve operational efficiency for handling bulky loads

CRIUS rigid arm industrial manipulator is an handling systems that, thanks to its structure with rigid steel arms, allow complex rotations and inclinations to be performed, even when the load’s centre of gravity does not coincide with the centre of mass.

The ADAN series pneumatic manipulators are the ideal solution to support operators in the lifting, handling and positioning of heavy and bulky loads. Maniflex solutions with rigid articulated arms also allow a single operator to safely handle considerable loads with total control and precision, reducing the risk of injuries, optimizing working times and increasing overall productivity.

How do rigid arm pneumatic industrial manipulators work?

The ADAN series manipulators, equipped with special gripping tools, are designed to handle components whose center of gravity is offset from the vertical axis of the arm. Their structure has been designed to guarantee resistance to torsion caused by this particular condition of use, allowing the manipulation of the load in zero gravity conditions.

Installation flexibility

The ADAN series pneumatic manipulators offer different installation options to suit your space and work area layout needs. They can be mounted on columns fixed to the floor or on self-stable bases, which allow them to be moved by a forklift or pallet truck. In addition, they can be installed on the wall or on floor or ceiling rails. Upon request, additional special supports are available, customizable according to specific customer needs.

Safety and reliability

For maximum safety, the manipulators are equipped with two brakes on the main axis and the intermediate joint. Operation is provided by filtered (40 μm) and non-lubricated compressed air (min. 0.7/0.8 MPa), ensuring reliable and long-lasting operation.

Advantages:

- Wide freedom of load positioning

- High speed in handling operations

- Global optimization of the production process

- Ease of management and intuitive interaction

- Greater safety and reduction of accidents

- Efficiency in operating costs

- Adaptability and flexibility to production changes

- Elimination of the risk of accidental load drops

Technical features:

- Maximum capacity: from 750 kg

- Maximum radius: 4,500 mm

- Vertical lift: 2,450 mm

- Maximum air consumption: 270 nl/min

CRIUS rigid arm industrial manipulator - some possible mounting options

Some examples of mounting options for the CRIUS series

Floor mounted column fixed on the ground with chemical anchors

Baseplate mounted free standing

Column mounted with baseplate on floor rails

Overhead or wall mounting bracket

Rail mounted overhead trolley system

Ceiling mounted bridge system combined with floor rails