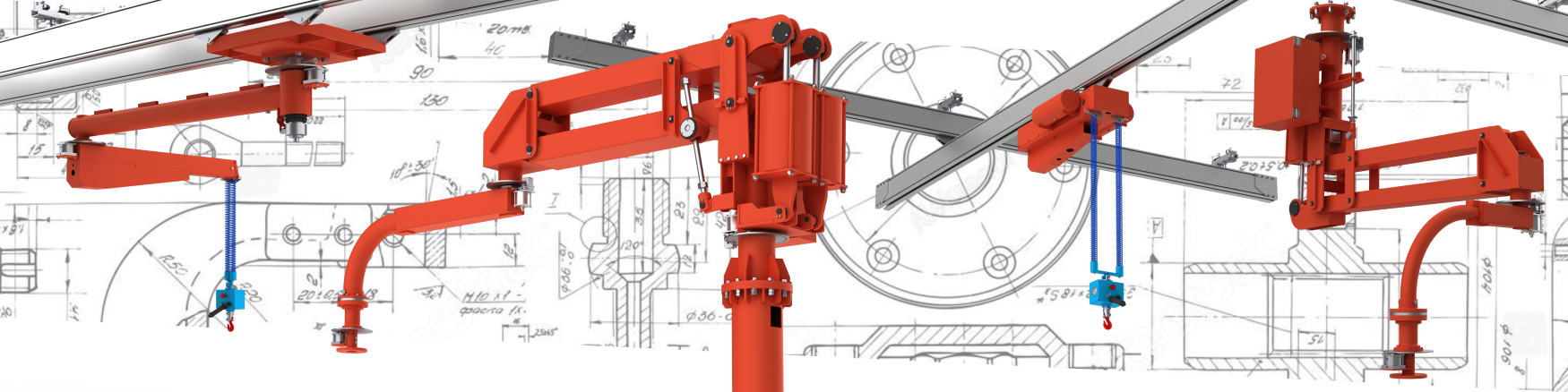

Industrial pneumatic manipulators

Rope type or rigid arm?

Industrial manipulators are versatile and powerful machines that simplify and optimize the handling of loads in various work contexts. The choice between a rigid arm or rope manipulator depends on several factors, including the weight, shape and size of the load to be handled, the ergonomics and safety of the operator and the specific needs of the production process.

Rigid arm manipulators

A rigid arm manipulator is a machine with a steel structure that offers great precision and flexibility of movement. It allows for pneumatic rotations and inclinations, even when the center of gravity of the component does not coincide with its center of mass.

Pros

- Precision: The rigid arms guarantee precise control of the load, allowing it to be positioned accurately even in tight spaces.

- Flexibility: The variety of possible movements makes rigid arm manipulators suitable for a wide range of applications

- Ergonomics: They reduce the physical effort of the operator, preventing injuries and fatigue

- Safety: They offer a high level of safety thanks to protection systems and sensors

Cons

- Cost: Rigid arm manipulators are generally more expensive than wire rope manipulators.

- Space requirement: The rigid structure requires a larger space requirement than a cable manipulator

- Load capacity: The load capacity is lower than that of similarly sized wire rope manipulators

Application examples:

- Component Assembly: Rigid-arm manipulators are ideal for precisely positioning delicate components during assembly.

- Heavy Load Handling: They can be used to lift and move heavy loads in a safe and controlled manner.

- Working in confined spaces: The flexibility of the rigid arms allows working in confined and difficult-to-access spaces.

Rope Manipulators:

A rope manipulator is a lifting system that uses steel or nylon ropes to move loads vertically. The movement occurs through a pneumatic cylinder that, by extending or retracting, wraps the ropes and moves the load up or down.

Advantages:

- Cost: Wire rope manipulators are generally cheaper than rigid arm manipulators.

- Space: They require a small footprint, fitting into limited work spaces.

- Load capacity: They offer a higher load capacity than rigid arm manipulators of the same size.

Disadvantages:

- Accuracy: Vertical motion offers less accuracy than rigid-arm manipulators.

- Flexibility: Movements are limited to the vertical direction.

- Ergonomics: They may be less ergonomic than rigid-arm manipulators, requiring greater operator effort for lateral movement of the load.

Application examples:

- Light Load Handling: Wire rope manipulators are ideal for lifting and moving light loads of standard shapes.

- Storage and retrieval of goods: They are used in warehouses and distribution centers to speed up the storage and retrieval of goods.

- Material Handling on Construction Sites: They can be used on construction sites for handling building materials such as bricks, tiles and beams.

In conclusion:

The choice between a rigid arm or cable manipulator depends on a careful evaluation of the specific needs of the production process. Factors to consider include the weight, shape and size of the load to be handled, the ergonomics and safety of the operator, the available budget and the specific characteristics of the work environment.