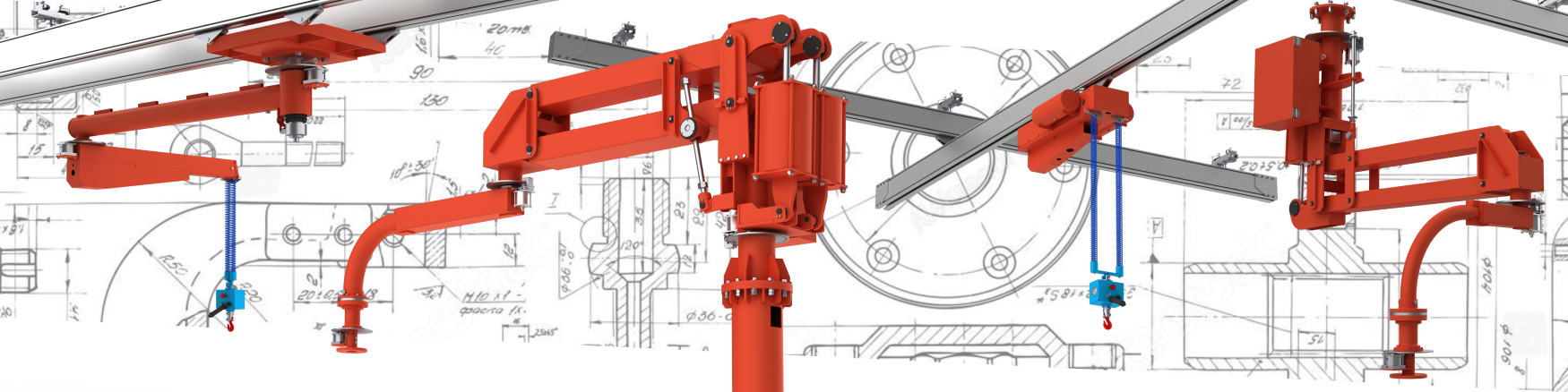

Industrial manipulators

What are Industrial Manipulators?

Industrial manipulators are machines designed to facilitate and optimize the handling of heavy loads in various industrial contexts. They are flexible and versatile systems that can be used to lift, lower, rotate and move components of different shapes, weights and sizes.

Main features

- Rigid arms or ropes: Industrial manipulators can be equipped with rigid arms, which offer greater load capacity and precision of movement, or ropes, which guarantee greater ergonomics and fluidity while still offering excellent load capacity.

- Operation: They can be operated manually, pneumatically, hydraulically or electrically.

- Load capacity: Load capacity varies depending on the model selected.

- Safety: Industrial manipulators are equipped with safety systems to protect the operator from any risks.

Main functions

- Heavy Load Handling: Industrial manipulators are used to move heavy loads that cannot be moved manually by an operator.

- Assist the operator to carry out repetitive tasks even in the presence of loads that are not necessarily heavy but difficult to manage.

- Moving loads in hard-to-reach places: Industrial manipulators can be used to move loads in places that are difficult to reach manually, such as high shelves or confined spaces.

- Injury Prevention: Industrial manipulators help prevent workplace injuries caused by manual handling of heavy loads.

- Increased Productivity: Industrial manipulators help increase productivity as they allow loads to be moved faster and with less effort.

Types of Industrial Manipulators

- Pneumatic manipulators: They are the easiest and fastest to operate and are suitable for use in environments subject to ATEX regulations.

- Hydraulic manipulators: These are the ones with the greatest load capacity, but they are also the least precise and fast to use.

- Electric manipulators: They are the most ergonomic and simple to operate, but cannot be used in ATEX environments.

- Manual manipulators: They offer greater fluidity of movement and high positioning accuracy, but their load capacity is lower.

Why use industrial manipulators

- Safety: Industrial manipulators help prevent workplace injuries caused by manual handling of heavy loads.

- Productivity: Industrial manipulators help increase productivity as they allow loads to be moved faster and with less effort.

- Ergonomics: Industrial manipulators reduce physical effort on the operator and improve ergonomics during production processes.

- Flexibility: Industrial manipulators are flexible and versatile systems that can be used for different applications.

Industrial manipulators are therefore an important investment for companies that want to improve safety, productivity and ergonomics at work.