Industrial pneumatic manipulators

How do pneumatic manipulators work?

Maniflex Industrial Manipulators: Power, precision and safety for load handling

Maniflex pneumatic manipulators are a versatile and reliable solution for handling loads in various industrial sectors. Powered by compressed air, they offer a combination of power, precision and safety that makes them ideal for a wide range of applications.

How do pneumatic manipulators work?

The movement of the gripping tools is controlled by pneumatic valves, the position of which varies according to the structure and type of load to be handled.

Automatic weight balancing

One of the key features of Maniflex pneumatic manipulators is the automatic weight balancing system. When handling loads with the same weight, the system, calibrated during the first phase of use, guarantees a smooth and precise movement.

For loads with different weights, the balance can be adjusted manually using a regulator easily accessible to the operator.

Guaranteed safety

Safety is a fundamental aspect for Maniflex . In case of interruption of the pneumatic supply, the system slowly moves downwards until it reaches the mechanical stop or the ground, ensuring complete control of the load in any situation.

Main features:

- Lifting speed: up to 30 m/min

- Noise level: less than 70 Db (A)

- Brakes on the main axle and on the intermediate axle joint

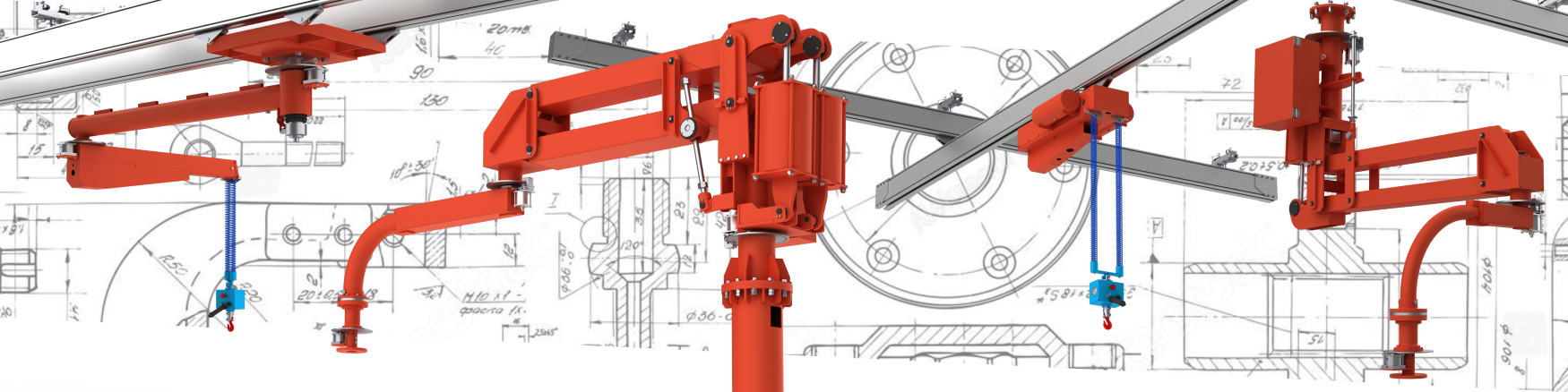

- Available in different configurations: column mounted, overhead mounted, rail mounted

- Rigid arm or articulated rope arms

- Suitable for ATEX zones

Maniflex pneumatic manipulators are perfect for:

- Reducing physical efforts

- Increasing productivity and efficiency

- Improving workplace safety

- Meet the specific needs of each customer thanks to the wide range of options available

Choose Maniflex pneumatic manipulators for safe and reliable handling of your loads.