Rigid arm manipulator

Ideal for any sector and application field including:

Automotive

Food Industry

Chemical

Construction

Electromechanical

Pharmaceutical

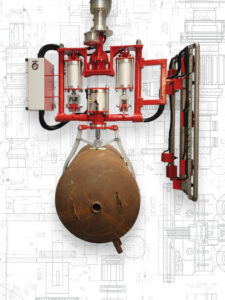

Foundries

Packaging

Woodworking

Textile

Mechanical

Ceramic

Home appliances

Tobacco

Tire production

Rubber and plastic

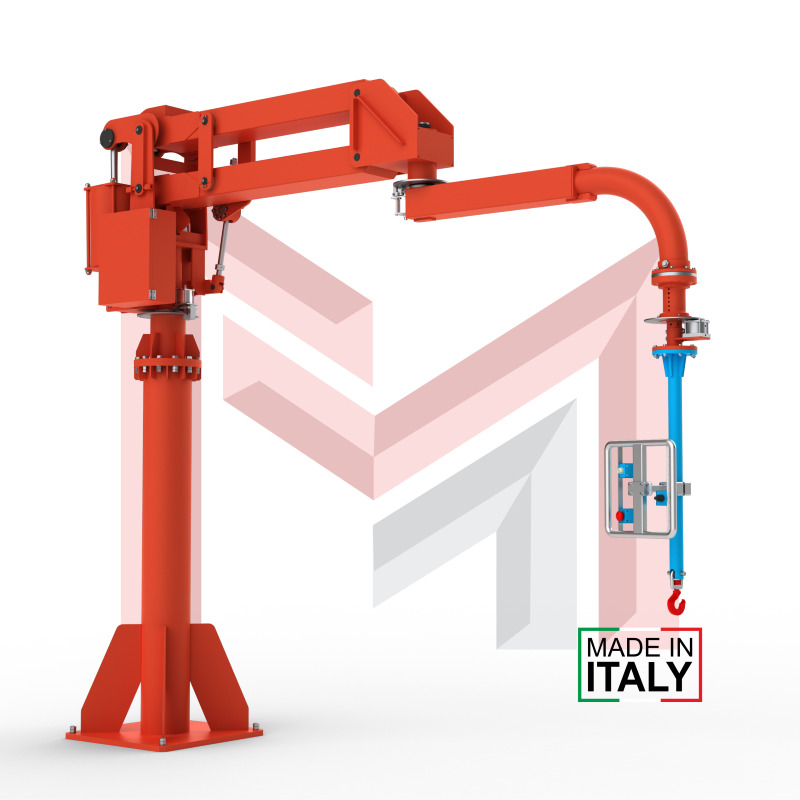

LITUS

Ergonomic lift assist manipulator

Ergonomic lift assist manipulator for heavy loads up to 1200 kg, with articulated arms, for manoeuvring, rotating and positioning loads in production lines where reliability, precision and speed are essential elements.

Ergonomic systems for safe and controlled load handling

LITUS ergonomic lift assist manipulator also known as pneumatic balancer offers exceptional support to operators during lifting, handling and positioning of heavy loads in all fields of application. Thanks to its design and rigid steel arms, this pneumatic manipulator allows complex movements, such as rotations and inclinations, even in situations where the load’s center of gravity is off-center. Maniflex solutions allow a single operator to handle significant loads safely and precisely, reducing the risk of injuries and at the same time optimizing working times, thus increasing overall productivity.

How do rigid arm industrial manipulators work?

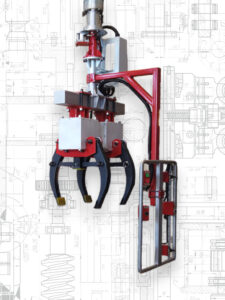

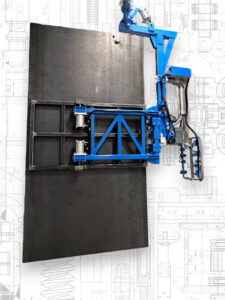

LITUS manipulators, equipped with special gripping tools, are designed to handle cantilevered loads. Their structure has been engineered to ensure a high level of load control, allowing effective handling in the absence of gravity.

Installation flexibility

LITUS manipulators offer a variety of mounting options, including fixed columns, self-supporting mobile bases, transportable by forklift or pallet truck, wall fixings and installations on rails. This versatility allows the manipulators to be adapted to any work environment, ensuring maximum operational efficiency.

Safety and reliability

To ensure maximum safety, LITUS manipulators are equipped with brakes on the rotation axis of the arm. Furthermore, they operate with filtered (40 μm) and non-lubricated (min. 0.7/0.8 MPa) compressed air, ensuring reliable and long-lasting operation.

Advantages of LITUS ergonomic lift assist manipulator

- Multidirectional freedom of movement in limited spaces

- Rapid grip and release with optimized work cycles

- Production efficiency with guaranteed operational continuity

- Ease of use with intuitive controls

- Increase workplace safety with reliable tools

- Saving operating costs through automation and precision

- Production flexibility to adapt to diversified sectors

- Consistent quality and precision

Technical features:

- Maximum capacity: 1,200 kg

- Maximum radius: 4,500 mm

- Vertical lift: 2,200 mm

- Maximum air consumption: 475 nl/min

Mounting options for model LITUS ergonomic lift assist manipulator

Some examples of mounting options for the LITUS series

Floor mounted column fixed on the ground with chemical anchors

Baseplate mounted free standing

Column mounted with baseplate on floor rails

Overhead or wall mounting bracket

Rail mounted overhead trolley system

Ceiling mounted bridge system combined with floor rails