ROPE MANIPULATOR

Ideal for any sector and application field including:

Automotive

Food Industry

Chemical

Construction

Electromechanical

Pharmaceutical

Foundries

Packaging

Woodworking

Textile

Mechanical

Ceramic

Home appliances

Tobacco

Tire production

Rubber and plastic

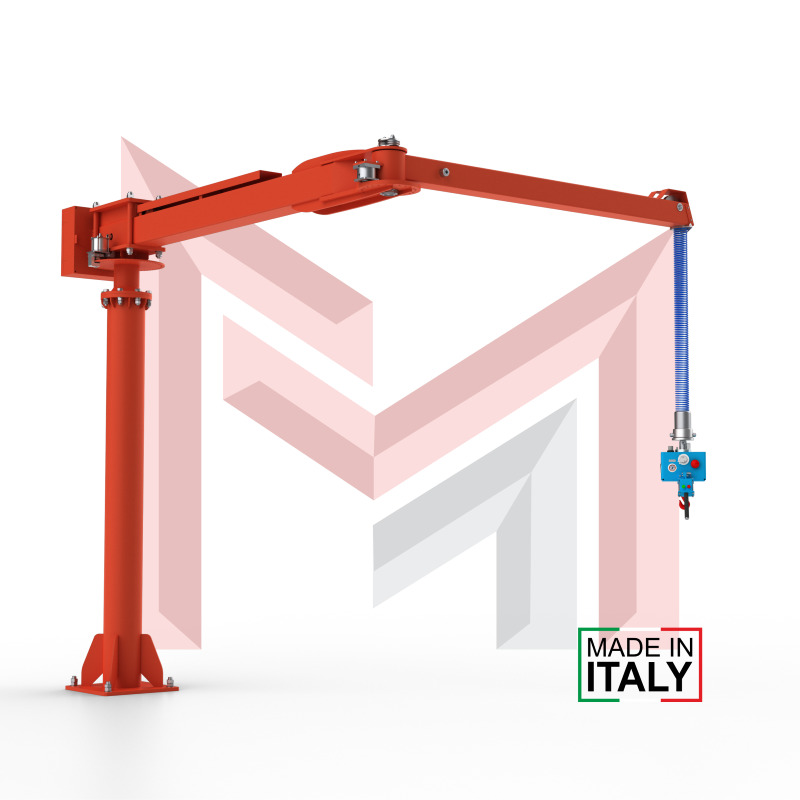

REA

Balancing arm cable manipulator

Extremely compact manipulator with articulated arm system and double rope balancing system, maximum capacity 180kg, particularly suitable for wide-ranging applications, for lifting and positioning loads without requiring any effort by the operator.

REA balancing arm cable manipulatir is an ergonomic solution for repetitive movement of heavy loads with zero gravity

The REA series industrial pneumatic manipulators are tools designed to support operators in repetitive operations of handling, lifting and moving heavy or bulky loads. Production and logistics activities that involve such tasks, performed manually on a daily basis, involve risks for both worker safety and the integrity of materials. Maniflex ergonomic manipulators offer the ideal solution, allowing operators to work ergonomically and efficiently, eliminating the need for physical effort thanks to the zero gravity system.

How do pneumatic industrial cable manipulators work?

The articulated arm is designed to offer optimal operation: two steel cables connected to the pneumatic cylinder ensure smooth movement of loads by distributing the weight evenly. The manipulator takes care of supporting the weight, allowing the operator to control the movements without any physical effort.

Installation flexibility

The REA series pneumatic balancers offer different configurations: from mounting on a column anchored to the floor to a self-stable base, easily moved with a forklift or pallet truck. To adapt to various space and layout requirements, they can also be installed on rails fixed to the floor or ceiling, or mounted on the wall. Upon request, additional types of special supports are available, customizable according to the specific needs of the customer.

Safety and reliability

REA manipulators are designed with the utmost attention to safety: two brakes on the main axis and on the intermediate joint ensure optimal control of the load. Filtered compressed air (40 μm) without lubrication is used for operation, maintaining a minimum pressure of 0.7/0.8 MPa for stable and long-lasting use.

Advantages of REA balancing arm cable manipulator

- Better maneuverability and movement of heavy loads

- Fluidity and precision in movements

- Reducing the risk of accidents at work

- Increased operational efficiency

- Versatility in various production contexts

- Reliability and repeatability of processes

- Optimization of labor costs

- Rapid adaptation to new production needs

Technical features:

- Maximum capacity: 180 kg

- Maximum radius: 4,500 mm

- Vertical lift: 2,000 mm

- Maximum air consumption: 140 nl/min

Mounting options available for REA balancing arm cable manipulator

Some examples of mounting options for the REA series

Floor mounted column fixed on the ground with chemical anchors

Baseplate mounted free standing

Column mounted with baseplate on floor rails

Overhead or wall mounting bracket

Rail mounted overhead trolley system

Ceiling mounted bridge system combined with floor rails